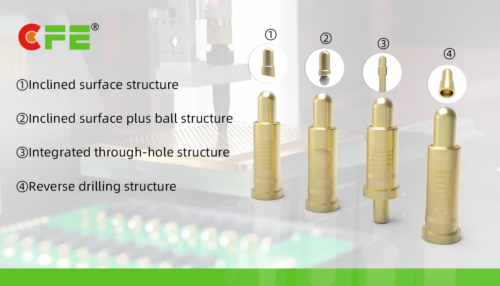

Four common design schemes for Pogo Pin

The internal structure design of the pogo pin is related to the mechanical performance, electrical performance, environmental performance, etc. The plunger is one of the core parts of the pogo pin. Common design schemes include inclined surface structure, inclined surface plus ball structure, through-hole structure and reverse drilling structure.

1. Inclined surface structure

In order to ensure that the plunger is in 100% contact with the barrel during operation, we cut one end of the plunger in contact with the spring into a bevel, and this design concept can ensure a stable low impedance.

Advantage:The resistance value of the resistance is small and stable, which can ensure the close contact between plunger and barrel ,and reach reduce the probability of instantaneous power failure.

2. Inclined surface plus beadstructure

In order to make the contact more stable, bead or insulating beads are added to the barrel to reduce the current passing through the spring, and the bead in the pogo pin have more stable contact. Therefore, there will be better performance in terms of electrical performance.

Advantage: The passing current is large, the contact impedance is small, and the performance is stable.

3. Through-hole structure

Through-hole pogo pin is the best choice for small size and high current, electricity is passed directly through the plunger, when the inner wall of the barrel is polluted by insulating media such as oil, it can be energized normally without being affected. It has great advantages in application in specific industries.

4. Reverse drilling structure

This design is best for small size connectors, which can meet the customer’s elastic requirements in small size, because the length of the spring in this design can exceed the length of the barrel, in some cases where space is limited, we hollowed out the inside of the plunger to get more assembly space for the spring, so that a stable spring force and relatively more compression strokes can be obtained for customers to choose.

- Tel:: +86(769) 81668560-866

- Mob:: +(86)13798762170

- Fax:: + (86) 769-8288-2401

- Email:: cfe.ca@cfeconn.com

- Factory:: NO.5 East Street,Zhen Yuan Road.Wusha.Changan, DongGuan CityGuangdong Province, China